When working with precast concrete elements that require lifting anchors, the choice of rubber recess former can directly affect installation efficiency, safety, and final structural integrity. To ensure the lifting anchor performs as intended, it’s essential to match it with a compatible and high-quality rubber recess former that maintains shape, allows for secure fixation, and can withstand multiple reuse cycles under tough jobsite conditions.

Overview of Rubber Recess Formers in Precast Concrete

Function of Rubber Recess Formers in Lifting Anchor Systems

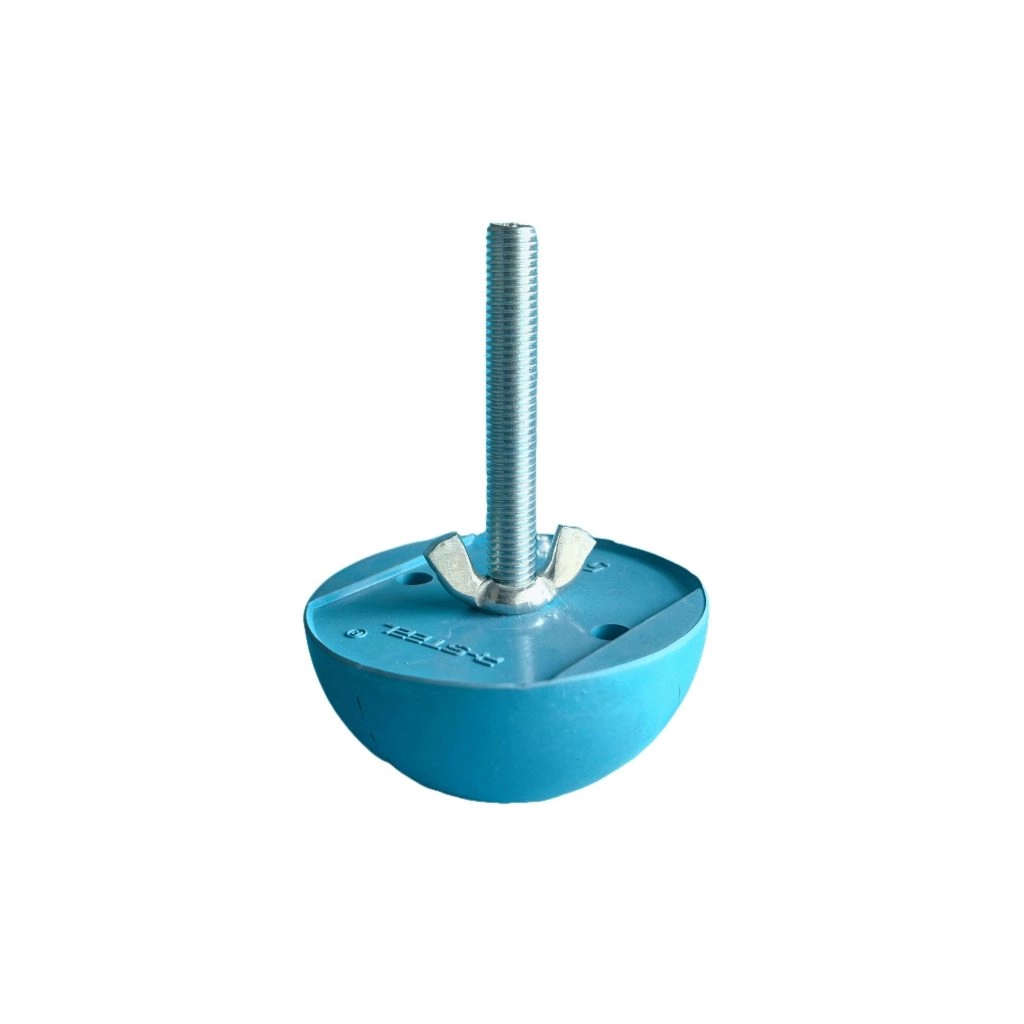

Rubber recess formers play a crucial role in creating precise voids within the concrete that accommodate lifting anchors. These formers are inserted into the formwork before concrete is poured. Once the concrete cures, they leave a clean recess that makes the lifting anchor accessible for later connection to lifting hardware.

The primary functions include:

- Ensuring accurate positioning of the anchor within the precast element.

- Creating consistent recess geometries for safe attachment of lifting clutches.

- Enabling efficient demoulding and later handling of heavy components.

A well-designed recess former prevents anchor misalignment and contributes to the overall lifting system’s load-bearing reliability.

Applications in Precast Concrete Construction

Rubber recess formers are widely used across various precast concrete applications:

- Vertical elements like wall panels.

- Horizontal elements such as floor slabs or beams.

- Structural members requiring exact lifting points.

They are compatible with a wide range of concrete anchors and load categories, allowing for both vertical and angled lifts depending on the anchor geometry and embedment depth.

Categories of Rubber Recess Formers Based on Anchor Type

R Anchor Rubber Recess Formers

These are tailored for use with R-type lifting anchors, which are often used for heavy-duty vertical lifting. The former creates a clean, circular recess that allows the R anchor head to remain flush or slightly embedded for secure lifting hook engagement.

- Optimized for load transfer during vertical hoisting.

- Commonly found in industrial and infrastructure-scale elements.

- Deliver consistent performance in high-weight applications.

Utility Anchor Rubber Recess Formers

Utility anchor systems are generally used in medium-load scenarios, where flexibility is more critical than maximum capacity. Rubber recess formers for utility anchors have a simpler design, often allowing quick placement and easy stripping.

- Adaptable to many precast shapes and forms.

- Suitable for repetitive production with rapid turnaround.

- Their straightforward structure minimizes setup time on-site.

Spread Anchor Rubber Recess Formers

Spread foot anchors require rubber formers that support wide load distribution. These types ensure even stress dispersion during lifting, reducing localized tension within the concrete.

- Essential for handling large façade panels or oversized structural elements.

- Minimize risk of cracking by improving stress flow across a broader area.

- Often paired with reinforcement cages for extra strength.

Key Factors When Selecting a Rubber Recess Former

Compatibility with Anchor Type and Load Requirements

Always begin selection by verifying that the former’s internal geometry matches the anchor head shape. If there’s any mismatch, the lifting clutch may not engage properly or could damage the concrete.

Also consider:

- Anchor rated load (e.g., 1.3T, 2.5T, etc.)

- Load direction (vertical or diagonal)

- Recess depth needed for safe clutch clearance

Material Durability and Performance Characteristics

High-quality rubber matters more than it might seem. Inferior materials deform over time, especially under repeated casting heat and mechanical pressure.

Look for rubber formers that offer:

- Heat resistance during curing

- Minimal compression set

- Consistent elasticity after multiple uses

BaoQi, as a manufacturer and supplier specializing in forged and cast metal components, also provides durable rubber solutions engineered for longevity and accuracy.

Dimensional Accuracy and Mold Fitment

Precision is critical. A recess former must sit tightly within the mold or risk shifting during pour. Even minor misalignments can result in an unusable void or incorrectly placed anchor.

Importance of Material Quality in Long-Term Use

Resistance to Wear, Tear, and Chemical Exposure

During demoulding, aggregate particles can abrade the rubber surface. Additionally, admixtures in concrete can degrade lower-quality rubber over time.

Choose materials that:

- Withstand mechanical abrasion

- Resist chemical corrosion from curing agents

- Retain shape even after frequent use

Temperature Tolerance During Casting Curing Cycles

In many production lines, curing temperatures may fluctuate between 30–70°C depending on steam curing practices. Rubber recess formers must maintain their shape across this range without warping or melting.

Installation and Maintenance Guidelines for Optimal Performance

Proper Installation Techniques for Secure Placement

Before pouring concrete:

- Verify that the anchor is properly seated in the former.

- Secure the former to the mold using mechanical fasteners or magnetic bases (for steel forms).

- For vertical elements, additional bracing may be needed to prevent slippage.

Tips for Efficient Demoulding Without Damage

Post-curing:

- Apply a compatible release agent to simplify removal.

- Gently twist or pull out the former instead of forcing it.

- Inspect each former after stripping to catch early signs of wear.

Maintenance Practices to Extend Product Life Cycle

After each cycle:

- Wash off residual cement paste or admixtures.

- Store dry and flat in shaded areas away from direct sun or chemical exposure.

- Avoid stacking under heavy weight to prevent deformation.

Troubleshooting Common Issues in Usage Scenarios

Misalignment or Movement During Casting Process

If a recess former shifts mid-pour:

- Check mold fit and whether fixation points are secure.

- Consider magnetic fixing systems or pre-drilled brackets to hold the former firmly in place.

Deformation After Multiple Uses or High Loads

Rubber formers have a lifespan. If you notice permanent warping or cracking:

- Retire the unit from service.

- Replacing worn units is safer than risking improper anchor engagement during lifting operations.

Cost Considerations When Buying Rubber Recess Formers

Balancing Price with Durability and Reusability

Don’t get caught up comparing only upfront cost. Consider how many cycles each unit will last — cost per use is what truly matters.

| Product | Unit Cost | Expected Uses | Cost Per Use |

| Budget Grade Former | $2.50 | 5 | $0.50 |

| High-Durability Former | $6.00 | 20+ | $0.30 |

Comparing Bulk Purchase Discounts Across Vendors

For high-volume precasters, explore:

- Annual supply contracts

- Volume discounts for standard sizes

- Vendor-managed inventory programs

Additional Accessories Related to Precast Lifting Anchors

To speed up operations or enhance safety:

- Magnetic fixing systems minimize setup time in steel forms.

- Reinforcement cages can be fabricated around anchor positions to improve load transfer during lifts.

Collaborating with BaoQi for Your Project Needs

BaoQi offers a wide range of precast accessories including rubber recess formers, anchors, magnets, etc. With capabilities in CAD-supported design, prototyping, forging/casting manufacturing, and global supply chain support, BaoQi is equipped to provide both off-the-shelf and bespoke solutions tailored to your construction project requirements.

FAQ

Q1: Can rubber recess formers be reused?

Yes, high-quality ones can be reused 20+ times if maintained properly.

Q2: What release agent should I use?

Use a rubber-compatible release agent approved for precast applications — avoid solvents that degrade elastomers.

Q3: Are magnetic fixings strong enough for vertical molds?

Yes, if sized correctly. They’re commonly used in steel formwork systems for fast setup.

Q4: How do I check if the former fits my anchor?

Request technical drawings from your supplier and confirm dimensions match your anchor’s head geometry.

Q5: Do I need different formers for angled lifts?

Potentially yes — check your anchor system’s requirements for clutch engagement angle and recess geometry.