Advantages of Aluminum Window Frames in Modern Architecture

Durability and Corrosion Resistance in Urban Environments

Aluminum window frames are a favorite in today’s building world because they’re super tough and don’t rust easily. Cities throw a lot at buildings—think pollution, wet air, or wild weather swings—that can ruin stuff like wood or steel over time. Aluminum, though, has a trick: it builds a natural shield, a thin oxide layer, that fights off rust and damage from rough conditions. This makes it awesome for places like beach towns or busy factory areas where the air’s not so friendly.

On top of that, the aluminum used in buildings often gets special treatments, like anodizing or powder coating. These add a tough layer to fend off rain, sun, and wind. So, the frames stay solid and look sharp for years, meaning you won’t need to swap them out often.

Lightweight Properties That Support Structural Efficiency

One cool thing about aluminum is how light it feels. It weighs way less than steel but still holds up strong. This lets builders dream up bigger windows without worrying about the building getting wobbly.

Plus, being light makes it easier to haul and set up these frames. That saves time and cash on workers. For super tall buildings, keeping things light is a big deal, and aluminum makes it happen without a hitch.

Low Maintenance Requirements for Long-Term Performance

Unlike wood frames that need constant painting or sealing, aluminum windows are a breeze to look after. Their smooth surface doesn’t soak up water, so they won’t twist or rot away. A quick scrub with mild soap and water keeps them sparkling.

This low-effort care saves money down the road. For businesses or property managers trying to keep costs down, aluminum’s a smart bet.

Energy Efficiency and Thermal Performance of Aluminum Window Systems

Thermal Break Technology in Aluminum Frames

Back in the day, folks thought aluminum wasn’t great at keeping heat inside compared to wood or uPVC. But now, clever new methods have fixed that with something called thermal break technology.

Here’s the deal: they stick a non-conductive material, like polyurethane, between the frame’s inner and outer parts. This stops heat from sneaking out or cold from creeping in. The frame stays tough and looks good while helping keep rooms cozy, cutting down on heater or AC use.

Contribution to Sustainable Building Certifications

Aluminum windows that save energy can help buildings snag green awards like LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method).

These windows cut energy use by trapping heat better and letting more daylight in through slim frames with bigger glass. Also, aluminum’s 100% recyclable, and it doesn’t lose its strength when recycled. That fits right in with eco-friendly building goals that focus on reusing stuff.

Safety, Security, and Fire Resistance Features

Strength-to-Weight Ratio for Enhanced Structural Integrity

Aluminum’s got a great mix of being strong without weighing a ton. That makes it perfect for jobs needing toughness but less bulk. This balance keeps windows safe, handling stuff like gusty winds or random bumps without breaking.

In big commercial spots with huge glass panels, you need frames that can hold heavy glass tight without being clunky. Aluminum nails this.

Fire-Resistant Properties of Aluminum Materials

Aluminum doesn’t burn—it just melts at about 660°C (1220°F). It’s not fully fireproof, but it’s way safer than stuff like PVC if a fire breaks out.

This matters a lot in tall buildings where fire rules are extra strict. Aluminum frames help stop flames from spreading through windows, giving an extra layer of safety.

Why Aluminum Window Frames Are Suited for High-Rise and Commercial Applications

Wind Load Resistance at Elevated Heights

Tall buildings get hit with crazy winds up high. Aluminum frames are awesome because they’re stiff and can be shaped to handle heavy pressure and weight needs.

They also blend right into curtain wall systems, which you see a lot in skyscrapers. This keeps the building safe and working great, no problems.

Noise Reduction Capabilities in Dense Urban Settings

Cities are noisy—cars honking, construction banging, you name it. Aluminum frames, when paired with special glass like insulated glazing units (IGUs), do a solid job at keeping the racket out.

Custom-made aluminum parts fit super tight, blocking air leaks that let noise slip in. This makes them perfect for quieting down loud city spots.

Qingdao Baoqi Intelligent Co., Ltd. – Precision Forging Manufacturer Supporting Custom Solutions

Overview of Baoqi’s Manufacturing Capabilities and ISO-9001 Certification

Baoqi kicked off in 2010, making and shipping all kinds of forged, cast, and punched parts from Qingdao, China. Our factories stick to the ISO-9001 quality rules, so everything we make is top quality. With four plants near Qingdao Port, a big shipping hub, we get products out fast across the globe while keeping quality tight at every step.

Custom Forged Components for the Construction Industry

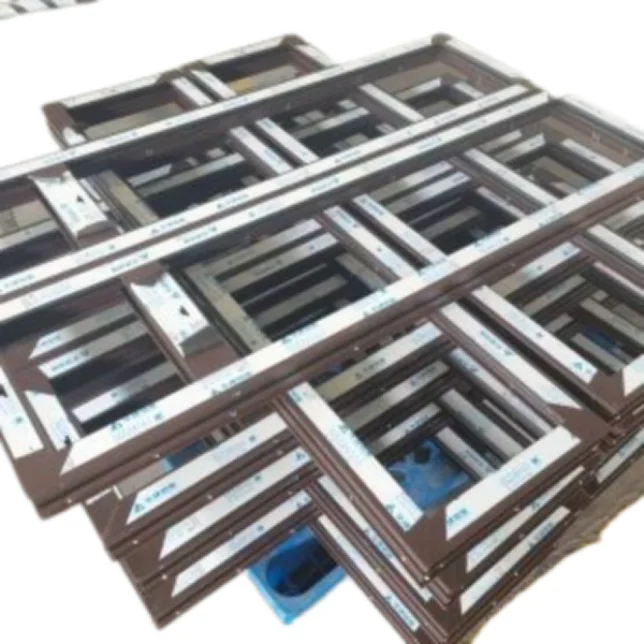

Baoqi’s got a wide range of services—think custom forging parts, stamping parts manufacturer, precision forging, metal casting manufacturer, laser cutting services, and CNC machining solutions. These are made to fit what industries like construction equipment or building hardware need.

For example, Baoqi crafts forged anchor channels and lifting sockets that work perfectly with aluminum window frame systems for commercial building fronts. These parts are strong and look great too.

Supplying High-Quality Metal Parts for Window Frame Systems

Baoqi makes stuff like lifting anchors (e.g., JLA050 5T), threaded socket systems (e.g., JLS12 M/RD12), cast-in loops, and connection boxes. These help attach windows to concrete structures securely.

These carefully made parts let builders pop in pre-made windows fast while meeting safety rules. That’s a huge help for commercial projects racing against tight deadlines.

Frequently Asked Questions (FAQ)

What makes aluminum windows better suited for high-rise buildings?

Aluminum’s light but super strong, so it can hold big glass panes and stand up to wind way up high. That makes it perfect for skyscrapers or tall office towers with curtain wall systems.

Are aluminum window frames energy efficient?

Yup. With thermal break technology, the frames stop heat from escaping, making them way better at insulation than old-school metal windows. They still look cool and stay tough.

Can aluminum windows help reduce noise pollution?

Totally. When used with double-glazed or laminated glass, aluminum frames with tight seals block out street noise. They’re great for places near busy roads or airports.

How long do aluminum window systems typically last?

If you install them right, anodized or powder-coated aluminum windows can last over 30 years with barely any care. They hold up against tough stuff like coastal humidity or city pollution.

Is there a customizable solution available if I need specific fittings?

You bet! Baoqi makes custom parts like forged or machined pieces just for your project. From lifting anchors for setting up windows to sockets for concrete walls, we’ve got you covered.

Want to know how our precision parts can help with your next building project using fancy window systems or façade elements? Get in touch today! BaoQi’s been around for over 10 years, making and shipping forging, casting, and punching parts. Our four ISO-9001-certified plants make sure you get great quality every time.