The Role of Corrugated Pipe in Modern Infrastructure

Corrugated pipes are really important for today’s building projects. They’re bendy, super tough, and don’t cost a ton. Their bumpy, ribbed look makes them strong but keeps them light as a feather. That’s why corrugated pipes work great for setups underground or above ground.

Common Applications in Drainage and Wastewater Systems

Corrugated pipes get used a lot for drainage and wastewater jobs. They move rainwater, sewage, or other liquids away from houses, shops, and factories. Corrugated HDPE pipes are awesome for drainage tasks, like handling stormwater or wastewater. They bend easily, so they don’t crack or break in different kinds of soil, even when things get rough.

Use in Electrical Conduits and Ventilation Systems

Corrugated pipes aren’t only for water. They also keep electrical wires safe. Their design protects cables from getting wet, hit by chemicals, or banged up. In ventilation systems, like HVAC stuff, corrugated pipes push air through tight or twisty spaces because they’re so flexible.

Benefits of Corrugated Pipe Design for Flow Efficiency

The ribbed outside of a corrugated pipe isn’t just for show. It helps the pipe stay strong. Some have smooth insides, which cuts down on rubbing. This lets water flow better without getting stuck. The combo of a tough outside and smooth inside keeps clogs away and handles lots of liquid, even when the flow changes.

Corrugated Pipe’s Features

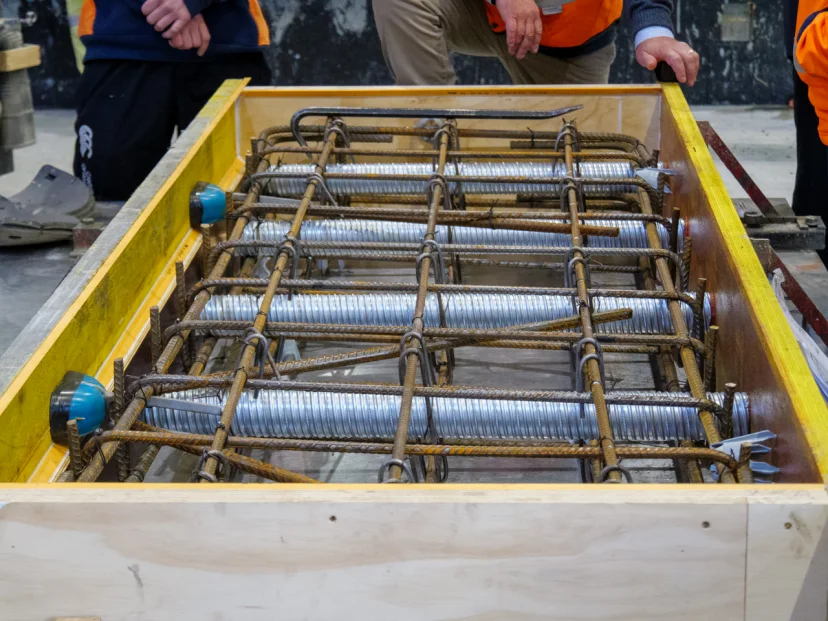

Unique Internal Corrugations

The corrugated pipe is designed with deep roll-formed internal corrugations, which offer an exceptional strength-to-weight ratio. This design provides enhanced durability and resistance to external pressures, ensuring reliable performance in demanding applications.

Resistance to Hydrostatic Pressures

The pipe’s construction resists distortions caused by hydrostatic pressures from surrounding concrete. This ability ensures that the pipe maintains its structural integrity even in challenging environments.

Secure Bond to Concrete

A socketed lockseam design minimizes any restrictions in the annulus during pile case retrieval, facilitating a strong and secure bond to the concrete, which is essential for reliable construction performance.

Cost-Effective and Versatile

With its high strength and low cost, the corrugated pipe offers versatility across various applications. Additionally, the reinforcing effect of the 4-ply lockseam results in considerable material cost savings, making it an economical choice without compromising on quality.

Key Factors to Consider When Choosing a Corrugated Pipe

Material Composition and Durability in Harsh Environments

Corrugated pipes come in different materials, and each has cool perks. High-Density Polyethylene (HDPE) is great because it fights off chemicals and bends well. It’s perfect for places with moving ground or harsh stuff. Polypropylene (PP) is lighter but stiffer, so it’s better when you need something that holds its shape.

Load-Bearing Capacity and Soil Compatibility

A corrugated pipe has to deal with pressure from inside and outside, like dirt piling up or cars driving over it. The ribbed design spreads out the stress nicely. You also gotta check the soil—sandy, clay, or rocky—to pick the right thickness and strength for the pipe.

Resistance to Corrosion, Chemicals, and UV Exposure

Pipes in tough spots, like places with strong chemicals or lots of sun, need to stay solid. Picking the right material is key. For example, UV-stabilized HDPE pipes hold up great under sunlight, which matters a lot for pipes used above ground.

How the Right Corrugated Pipe Impacts Drainage System Performance

Choosing the right corrugated pipe doesn’t just fix things now. It makes the whole system work better for years.

Preventing Blockages and Ensuring Continuous Flow

Getting the pipe size right is a big deal to avoid clogs. You need to figure out how much water will run through. Then, pick a corrugated pipe that can handle it without backing up. Smooth insides stop dirt from piling up, so water with bits in it flows through no problem.

Enhancing Lifespan of the Entire Drainage Network

One lousy pipe can mess up everything. Strong materials like HDPE, with well-made joints, stop leaks and keep roots from sneaking in.

Reducing Maintenance Costs Through Proper Selection

Spending a bit more on good corrugated pipes saves cash later. Pipes that fit your project’s needs don’t need fixing as often. The right size also keeps the system from getting overloaded, which can mean pricey repairs.

The Importance of Customization in Corrugated Pipe Solutions

Every project is different, so the parts should be too. Customizing corrugated pipes makes sure everything fits just right.

Meeting Project-Specific Requirements with Tailored Designs

Some jobs need pipes with special sizes or connections. Maybe you’re working in a cramped spot or linking to old systems. Custom corrugated pipes make it all work smoothly without risking safety or performance.

OEM Casting Supplier Capabilities for Specialized Components

Big projects need more than just regular parts. OEM casting suppliers make special fittings, like flanges or couplers, that match exact needs. They use stuff like sand casting or die casting, depending on how tricky the part is. Sand casting is super common in industries like cars, farming, and construction.

Advantages of Partnering with a Forging Manufacturer for Custom Parts

Forged parts are way stronger than cast ones, which is great for high-pressure jobs. A good forging manufacturer makes sure every part is top-notch and gets delivered on time. That’s a must for big building projects. China has tons of manufacturers who are experts in different casting methods.

Qingdao Baoqi Intelligent Co., Ltd.: Supporting Reliable Drainage Solutions

Qingdao Baoqi Intelligent Co., Ltd. offers laser cutting services, CNC laser cutting metal, and sheet metal laser cutting. With over 10 years of experience in forging, casting, and punching parts—including precast mold accessories like threaded socket systems—we help with custom needs all over the world.

Our factories are certified with the ISO-9001 quality standard. That means every part meets tough industry rules before it heads out.

Frequently Asked Questions (FAQ)

What is a corrugated pipe used for?

A corrugated pipe is mostly used for drainage systems, like moving stormwater or wastewater. It’s also great for protecting electrical wires, pushing air in HVAC systems, or helping with farm irrigation because it’s strong and bendy.

What material should I choose for my corrugated pipe?

HDPE (High-Density Polyethylene) is a top choice because it fights off chemicals and sun damage while staying flexible. It’s perfect for tough soils or harsh spots. Corrugated HDPE pipes are ideal for many drainage applications.

How does pipe size affect drainage performance?

A pipe that’s too small can clog during big rain. One that’s too big costs extra for no reason. Figure out the water flow to pick the right size. Proper sizing helps prevent overloading the drainage system.

Can customized components improve my piping system?

You bet, especially for weird layouts or connecting to old systems. Custom fittings make everything work together while keeping the system strong.

Why choose Qingdao Baoqi Intelligent Co., Ltd.?

We’ve been making precision parts like lifting anchor systems and cast-in loops for over 10 years. Our four ISO-9001-certified factories offer laser cutting and custom solutions for big projects worldwide.

For more info on how our custom solutions can make your next project awesome—from precast accessories to CNC laser-cut metal parts—reach out today!